CHAPTER 7 DRILLING AND PRODUCTION UNDER SPECIAL CONDITIONS: TECHNICAL ISSUES RELATING TO OIL AND GAS OPERATIONS IN POTASH, TRONA AND COAL BEDS

| Jurisdiction | United States |

(2001)

DRILLING AND PRODUCTION UNDER SPECIAL CONDITIONS: TECHNICAL ISSUES RELATING TO OIL AND GAS OPERATIONS IN POTASH, TRONA AND COAL BEDS

Gemini Solutions, Inc.

Houston, Texas

[Page 7-1]

7.01 Introduction

7.02 Multi-Mineral Development of Oil and Potash in New Mexico, and Gas and Trona in Wyoming

[1] Introduction

[2] Known Potash Leasing Area (KPLA) of Southeastern New Mexico

[a] Producing Formations and Wellbores

[b] Geology and Rock Mechanics in the Vicinity of Mines

[3] Known Sodium Leasing Area (KSLA) of Southwestern Wyoming

[a] Producing Formations and Wellbores

[b] Geology and Rock Mechanics in the Vicinity of Mines

[4] Discussion

[5] Summary

7.03 Coalbed Methane

[1] Technical Overview of Coalbed Methane Production

[2] Coal Mines and Coalbed Methane in the Black Warrior Basin

7.04 Summary

7.05 References and Acknowledgments

[Page 7-2]

7.01 Introduction

The issues surrounding multiple mineral development are complex and involve numerous entities. Certain regulatory and legal decisions, however, should be based on sound science and engineering. When oil and gas operations are in or around subsurface mines, development of both resources will result in some interference. Either the mines and wells will have to be kept some specific distance apart, or the wells will need to be left in subsidence pillars to protect the wellbore. If the oil and gas company can't place wells in certain locations, oil and gas will be wasted. If the miners can't mine through or near an oil or gas field, or have to leave overly large pillars or buffer zones, unmined mineral will be wasted. The primary technical concern in these cases is safety. How close can a producing, shut-in, or plugged and abandoned well be to a mine and still be safe? Once the appropriate well to mine offset is determined, decisions regarding waste can be made more accurately.

The answers to the safety questions are case specific due to differences in types of oil and gas reservoirs and wellbores, mining techniques, and the characteristics of the geologic formations being mined. Several technical questions need to be answered. If a wellbore leaks, is the pressure inside the wellbore greater or less than the pressure outside in the formation being mined? If the pressure in the well is higher than the pressure in the mining interval, is the formation permeable enough to allow flow from the well to the mine? Is the wellbore pressure high enough to fracture the rock near the mine? Will mining induced subsidence cause the formation or geologic bedding planes to shift and crush the casing? Can the oil companies design a casing and cement system that will withstand these forces?

In the case of coalbed methane and coal mines, technical issues such as well spacing and flow of water and gas from the coal beds due to mining become important. The technical goal is to produce as much coalbed methane as possible before the mines de-water the coal seam and release the methane to the atmosphere.

The technical issues relating to three examples of multiple mineral development will be discussed in this paper; 1) potash mining and oil and gas production in southeastern New Mexico, 2) trona mining and gas production in southwestern Wyoming, and 3) coalbed methane production and coal mining in northern Alabama and Mississippi.

7.02 Multi-Mineral Development of Oil and Potash in Southeast New Mexico, and Gas and Trona in Wyoming

[1] Introduction

Over the past years, oil and gas and mining operations have been occurring in proximity to one another in both Southeastern New Mexico and Southwestern Wyoming. The two areas are, respectively, known as the Known Potash Leasing Area (KPLA) and the Known Sodium Leasing Area (KSLA). In New Mexico, the mines produce Potash (Sylvite (KCl+NaCl) and Langbenite (K2SO4 — 2MgSO4)), a mineral that is processed into fertilizer. In Wyoming, the mines produce Trona (Na2CO3 — NaHCO3 — 2H2O), a mineral that is processed into Soda Ash and used primarily

[Page 7-3]

by the glass manufacturing industry. Due to the similarity in the acronyms for the two regions, "Trona Area" will be used to denote the KSLA of Wyoming and "Potash Area" will be used to denote the KPLA of New Mexico. In both locations, oil and/or gas fields have been and are being developed. In some cases, the fields have typically been removed from mining operations (New Mexico and Wyoming), and in other cases, the oil and gas wells have been contained in pillars within the mines (New Mexico). The distances between mine operations and wells differ based on location, type of well, and safety concerns particular to each area. This section summarizes the technical issues relating to concurrent development of both oil and gas and mined minerals in the New Mexico Potash Area and the Wyoming Trona Area.

[2] Known Potash Leasing Area (KPLA) of Southeastern New Mexico

[a] Producing Formations and Wellbores

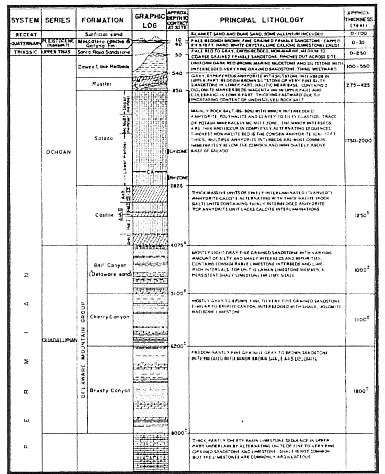

"Delaware" is the term given to wells completed in the Delaware Formation of Southeast New Mexico. The Delaware Formation is a sedimentary formation occurring as part of the Permian System (Fig. 1).

Figure 1 — Potash area geologic column

[Page 7-4]

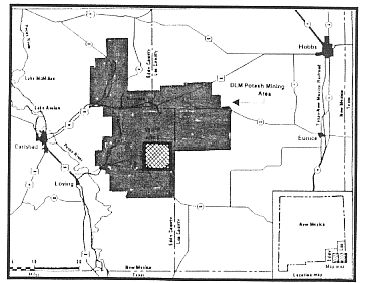

Oil and gas operators have drilled and either completed or plugged and abandoned several thousand Delaware wells in and around the Potash Area. The drilling and completion procedures vary slightly by company, but in general are quite similar. The completion procedures followed by operators in the Potash Area (Fig. 2 — green area) are set by the New Mexico OCD and approved by the BLM on Federal lands.

Figure 2 — New Mexico Potash area (KPLA)

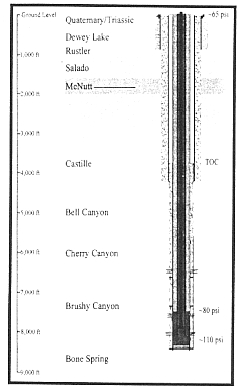

Casing strings are placed and cemented in each Delaware well to isolate the produced fluids from the Potash bearing Salado Formation (Figs. 3 and 4).

Figure 3 — Delaware well cemented to surface

Figure 4 — Delaware well cemented into "Salt String"

[Page 7-5]

The surface casing string set down into the Castille Formation is also called the "salt string." Outside of the Potash Area, this particular casing string is not required by the State, as it is not needed to produce the oil and gas. However, producing wells inside the KPLA are required to have this casing string to provide additional protection to the miners.

The petroleum reservoirs producing from the Delaware Formation typically produce oil, water and solution gas. The original reservoir pressure of a deeper Delaware well is approximately 3,000 psi at approximately 8,000 feet. Therefore, the average pressure gradient from the surface is 0.375 psi/ft. As the pressure gradients in formations are typically higher than 0.375 psi/ft, these Delaware reservoirs are considered to have subnormal pressures. This low pressure is due to the presence of the Salado Formation that occurs above the Delaware Formation (Fig. 1). The plastic nature of the Salado's pure halites provide a "hydraulic disconnect" between the hydrostatic pressure above the Salado and the sediments below the Salado. Delaware reservoirs produce under solution-gas-drive (see Chapter 6, Sections 1-3 for a description of reservoir rock and fluid properties and reservoir drive mechanisms). Solution-gas-drive, however, is not a strong drive mechanism, and these types of reservoirs experience a rapid decrease in reservoir pressure. Therefore, early in the life of a Delaware well, there is not enough reservoir pressure support to allow the oil and water produced from the reservoir to flow to the surface without assistance from an outside source. It is common in these types of reservoirs to use subsurface sucker rod pumps to supplement the reservoir pressure by lifting the oil and water to the surface. Due to the rapid reservoir pressure decline, and therefore, flowing bottom hole pressure decline, some companies place the wells on rod pump when they initially complete the well. Other companies will wait several months for the reservoir pressure to decline and then begin pumping the well. In either case, the reservoir pressure is typically less than one third of its original value within one year of being placed on production.

Figure 3 shows a wellbore diagram for a well that is being produced by rod pumping. For the pumping case, the wellbore pressure is maintained at a low value of approximately 80 psia. If the well is shut in using the typical procedure of first turning off the surface pumping unit, the fluid level in the annulus rises until the force exerted by the column of fluids balances the reservoir pressure. Under this situation, the gas in the wellbore remains at 80 psia. In the event that the valve at the surface is shut in and then the surface pumping unit is turned off, the annular gas pressure will rise as fluid moves into the well. The liquid water and oil will compress the gas in the annulus until the gas pressure plus the hydrostatic head of the liquids equals the reservoir pressure. If this situation occurred on the first day of production (highest possible reservoir pressure) and the reservoir pressure was high enough to move the liquid column up to the mining levels, the pressure of the gas in the wellbore at 1500' would be less than 400 psia. At any time later in the life of the well, the reservoir pressure and wellbore pressures will be lower than on the first day of production.

[b] Geology and Rock Mechanics in the Vicinity of Mines

Potash in the KPLA of New Mexico is mined from the McNutt member of the Salado Formation. The Salado Formation is a massive evaporite sequence consisting of halite (rock salt), argillaceous halite, and polyhalite. Observations from core holes and logs indicate that these beds are laterally continuous. The Salado Formation is approximately 2000 ft thick and the top of the formation in the main mining area is at a depth of about 850 feet. Thin interbeds of...

To continue reading

Request your trial