CHAPTER 5 TECHNICAL METHODS OF REMEDIATION AND PREVENTION OF GROUND WATER CONTAMINATION

| Jurisdiction | United States |

(May 1991)

TECHNICAL METHODS OF REMEDIATION AND PREVENTION OF GROUND WATER CONTAMINATION

TRC Environmental Consultants, Inc.

Englewood, Colorado

INTRODUCTION

This paper provides an overview of groundwater remediation technologies for attorneys and managers who are faced with the task of overseeing these projects. Rather than delving into all of the technical details needed to design and implement these systems, the focus is on general approaches, the rationale behind each method, and some of the limitations, so that the reader will have a better basis for ensuring that proposed remedies are consistent with overall strategies and long term goals at a site.

Before discussing individual technologies, a few general comments regarding groundwater remediation are in order:

1. The subsurface environment is nearly always complex and the models and assumptions used in remedial designs are, of necessity, gross simplifications. Experience and judgement are required to evaluate the impact of these simplifications, and to make allowances.

2. Design of structures like buildings and bridges involves materials such as steel and concrete that have predictable and relatively uniform properties, are easily tested and can be visually inspected. Design of groundwater remediation typically involves earth materials that have non-uniform and unpredictable properties, are difficult to test, and generally cannot be visually inspected. Therefore, the risks of failure or inadequate performance are much higher.

3. Many of the remedial methods currently being employed are emerging technologies, with few dependable design procedures. In fact, pilot testing may be more fruitful in some cases than spending inordinate amounts of time on investigations and designs that may be based on invalid assumptions. Changes in design and operating procedures should always be anticipated during implementation.

4. Notwithstanding the need for careful and thorough investigations, it is not necessary for every investigation to become a research project. For example, when complex alluvial environments with numerous small sand lenses are encountered, it should not be necessary to delineate each lens. However, the attribute of having numerous small and undefined lenses should be accounted for in design (e.g., by installing cutoff walls or drains that will intercept all lenses, wherever present).

Every instance of groundwater contamination is unique, and the techniques used to remediate groundwater must be adapted to site-specific conditions. Nevertheless, all remedies apply

[Page 5-2]

some of the general approaches shown on Figure 1 and listed below:

• source control

• plume containment

• plume interception

• plume extraction

• in-place treatment

• groundwater treatment and disposal

As more sites move from the investigation and design phases into implementation and cleanup, the limitations and realities of these technologies are becoming more apparent. The following discussion describes the fundamental concepts behind each of these approaches, explains when they are generally applicable, and identifies common misconceptions and problems with each method. Recent concerns raised over the efficacy of pump-and-treat technologies (EPA 1989 and others) are discussed in the section on plume extraction.

SOURCE CONTROL

Unless perpetual management of groundwater contamination is acceptable or the only practical solution, the source of the groundwater contamination should be eliminated. Typical methods of source elimination include:

• excavation and disposal

• stabilization (in-place)

• capping

• liners

Practical considerations and limitations of these methods are discussed below.

[Page 5-3]

Figure 1. GENERAL METHODS OF GROUNDWATER REMEDIATION

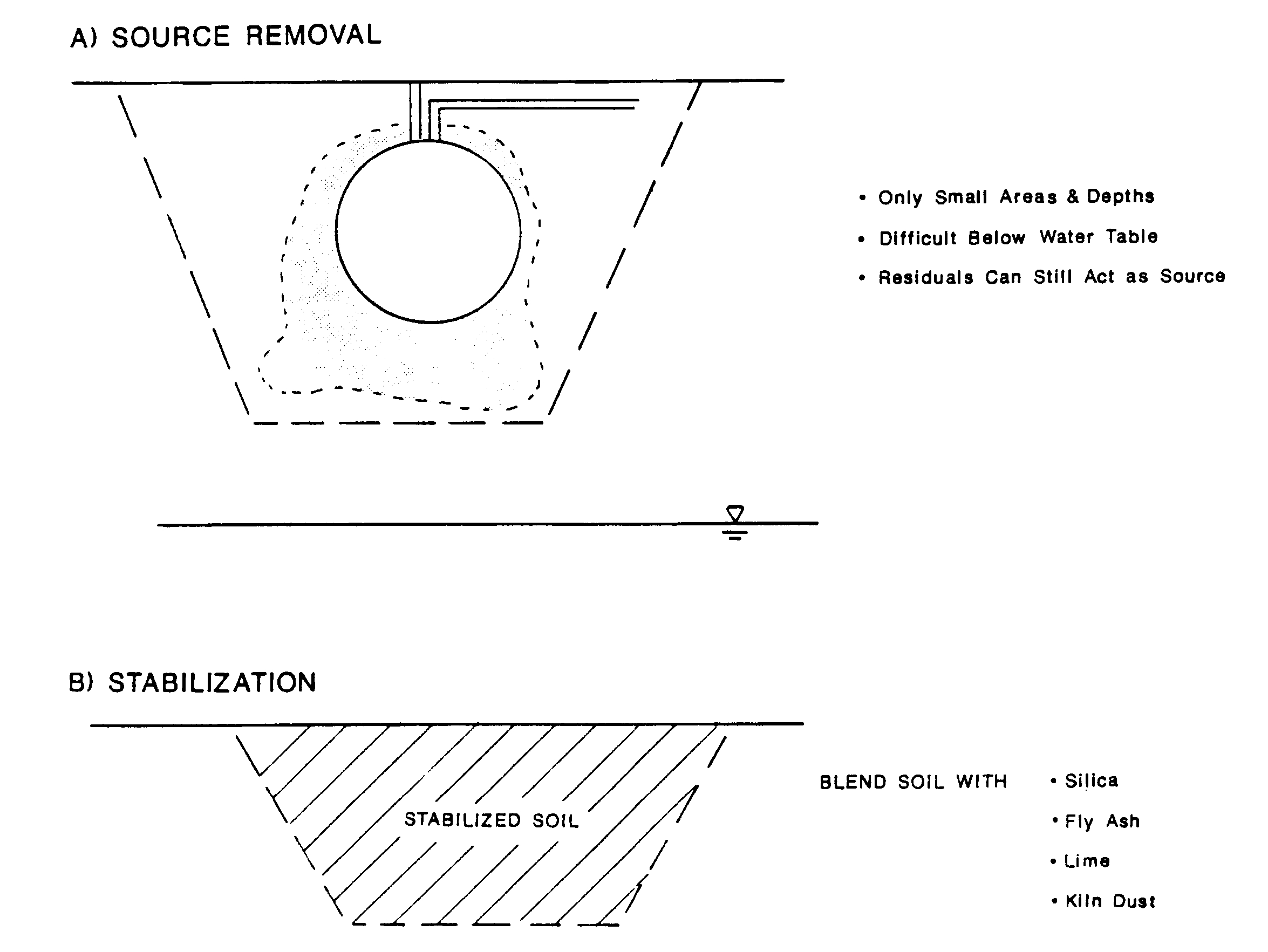

Figure 2 SOURCE ELIMINATION

[Page 5-4]

Excavation and Removal

Whenever the source of contamination can be identified and is of limited area and depth, excavation and removal of the material is usually the most practical and economic solution to eliminating sources of groundwater contamination. For example, small leaks, overfilling, and surface spills frequently lead to contamination of a small volume of soil around underground storage tanks (Figure 2), which is typically more economic to excavate and dispose (or treat) than to remediate in-situ. If all of the contamination can be removed, any threat of future groundwater contamination is eliminated.

There are several limitations to excavation of contamination. It is generally only cost effective when small quantities and depths are involved (typical excavation, hauling, and Subtitle D landfill disposal costs are in the range of $30 to $50/cubic yard in the Rocky Mountain region). Once contamination extends below the groundwater table, excavation generally becomes much more difficult, requiring dredging techniques or dewatering (and permitting and treatment or disposal of contaminated groundwater). Any residual contamination not removed may still act as a future source of groundwater contamination, so that other methods of remediation may still need to be employed. Finally, regulations such as the RCRA land disposal restrictions (40 CFR 268 ) may favor leaving certain wastes in-place.

Stabilization

An alternative to source removal is in-situ stabilization of wastes and contaminated soils. This entails adding chemicals which prevent or minimize leaching of deleterious compounds from the waste. This is typically a cementing process, involving the addition of reagents such as cement, kiln dust, fly ash, lime, or other binders to the waste. Silica (the most prevalent mineral in quartz or sand) may be used in liquid form to bind and encapsulate the particles. Other processes include soil flushing, chemical and biological degradation, application of heat or electric currents to convert the soil or waste into a vitrified (glass-like) compound, and aeration of volatiles (EPA 1984).

Bench tests and sometimes pilot-scale tests are required to determine the type and amount of stabilizing agents that are needed to reduce leachate concentrations to acceptable levels (EPA

[Page 5-5]

1989a). Costs for stabilization of near-surface deposits are highly variable, depending on the site location, type and quantity of reagent required, and waste type and quantity, but are frequently in the range of $30 to $100 per cubic yard.

Stabilization may be carried out in the ground, using mixing tools such as rakes or discs for shallow deposits, and specially designed large diameter drills for deeper deposits. Better results can be assured by excavating the material and adding the reagents in mixers before placing the stabilized material back in the excavation (or in a new disposal cell).

The most likely cause of failure of stabilization is inadequate mixing, resulting in pockets of waste that are still leachable. This is more likely to happen with in-situ mixing, and with clayey materials that do not break up very easily.

Capping

When sources are located above the water table, contamination usually results from infiltration of precipitation and leaching of contaminants from solids, or draining of liquid wastes (leaking drums, tanks, impoundments, and landfill leachate). Once free liquids are removed, stabilized, or have completely drained from the source, low permeability caps may be placed over the solid wastes to prevent further infiltration and leachate generation.

Caps may be constructed of clay, asphalt, or a combination of soil and plastic liners (geomembranes). The most suitable and cost effective material depends on regulatory requirements1 , and the degree of maintenance that can be provided.

Critical elements of design are the cap permeability and predicted rated of infiltration, surface runoff and erosion control, protection, and maintenance requirements to ensure continued cap integrity. In addition, the underlying material must have sufficient strength to support the cap

[Page 5-6]

and avoid settlement that causes cracking of the cap or ponding of precipitation in depressions.

The EPA has developed a field verified model (Peyton and Schroeder, 1988) for predicting cap performance, including infiltration, runoff, and lateral drainage in drain layers. Applications of this model at sites in the Rocky Mountain region by the author have shown that high evaporation rates and low precipitation result in highly effective soil caps with little or no predicted infiltration when optimally designed. On the other hand, some infiltration is typically predicted for soil and multi-layer caps (soil, geomembrane, and drain layers) in humid regions.

Liners

Liners are most commonly an element of new landfills and surface impoundments, designed to prevent groundwater contamination, rather than remedial technologies. Nevertheless, so many misconceptions exist regarding the properties and functions of liners that a brief discussion is warranted.

The greatest misconception surrounds the use of the term "impermeable", particularly when applied to clays or other natural, particulate materials. For example, a permeability of 10-7 cm/s has become a threshold for clay permeabilities, principally due to certain RCRA requirements for surface impoundment and landfill liners2 . In reality, a clay liner with a permeability of 10-7 cm/s can allow a significant amount of seepage to occur; for example, approximately 1 foot of water will seep through a 2 foot thick, 10-7 cm/s clay liner with a 17 foot depth of water over a one year time period. This is not necessarily a...

To continue reading

Request your trial